Akita Spare Parts Trading DWC-LLC

Akita Spare Parts Trading DWC-LLC

Plots FB-83 and FB-84

Dubai South Logistics District

Dubai

United Arab Emirates

Telephone+90 533 521 87 36

About us

In 1964, in the city of Osaka, Japan, in the wake of the industry growth, a company of enthusiastic scientists started Akita Kaihatsu, a small laboratory for verification and studying metals properties. During their scientific researches, Akita Kaihatsu specialists found a practical application for their knowledge.

In 1987, Akita Kaihatsu gains a membership of Japanese Engineering Standards Committee JISC, a permanent member of the International Organization for Standardization (ISO) and it is directly involved in the development and implementation of system standards for organizing quality management (ISO 9000) and environmental management (ISO 14000).In 2008, the company's management come to organize the production of auto parts under its own brand — LYNXauto. Production is carried out in 9 countries of the world, at our own enterprises and at the enterprises of partners.

Today

Today LYNXauto's production program includes more than 35 product groups and more than 25000 SKU.

More, than 70 of the largest distribution and dealer companies in the world successfully sell LYNXauto products.

Our Products

Brake discs and drums

- Ideal surface treatment provides convenient and predictable breaking straight after the new LYNXauto new discs and shoes maintenance

- Overheat resistance. Geometrical parameters do not break after extreme loads influence

- 100% balancing – provides the absence of vibrations during the exploitation

- Anti-corrosion coating makes attractive appearance of breaking disc, and due to this the whole car looks more presentable

LYNXauto brake discs and drums are manufactured using the most modern and advanced casting and machining methods. High-quality and ultra-precise working surfaces, combined with 100% automatic balancing, ensure the maximum contact patch with the brake pads and a long service life.

Optimum thermal conductivity of the material of the discs and drums contributes to the efficient removal of heat from the friction zone, which, together with a developed system of ventilation ducts, ensures predictable and reliable braking of the car in any conditions.

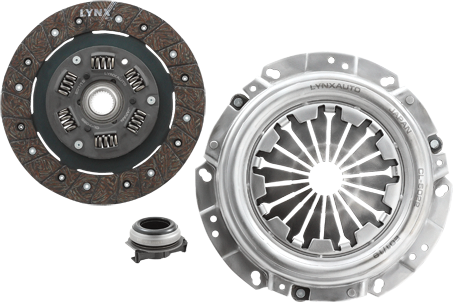

Clutch kits and components

- Friction linings with increased wear resistance provide a stable coefficient of friction

- High-quality and ultra-precise processing of the working surface of the pressure plate ensures efficient heat removal from the friction zone

- Diaphragm spring made of JIS G4801 high quality steel with precise dimensioning and precise geometry ensures optimum resilience performance

- Increased bearing capacity, high-temperature wear-resistant lubrication and hardening of working surfaces increase the durability of the release clutch

LYNXauto clutches are a high efficiency of torque transfer from the engine to the transmission, reliability, durability and driving comfort.

Depending on the applicability, the LYNXauto clutch kit includes: a pressure plate assembly with a "basket" diaphragm spring - a driven disc - a clutch assembly with a bearing - a flywheel. Every part of the clutch has improved performance.

CV-joints

- Durability exceeds the requirements of car manufacturers

- Increased resource

- Unique technologies

The LYNXauto product range includes both external and internal CV joints, as well as complete drives. LYNXauto CV joints meet the highest requirements for reliability and wear resistance. The tensile strength of LYNXauto CV joints is twice the requirements of automakers. Produced using advanced Japanese technology. The use of the arched profile of the ball raceways on the inner and outer cages of the hinge allows to significantly reduce the contact load and increase the service life and reliability of the LYNXauto CV joints. The use of a special lubricant and high-quality, low-temperature-resistant protective covers further prolongs the service life.

Shock absorbers, springs and their components

- Unique seal assembly design

- Adopted for harsh environments

- High strength against fatigue and reliable paint coating Balanced characteristics Extended service life

The main cause of shock absorber failure is damage or natural wear of the shock absorber rod. To eliminate these breakdowns and increase the durability of shock absorbers, Akita Kaihatsu engineers developed and implemented a sealing assembly with completely new design. The maximum reduction of friction and wear is achieved by applying a polytetrafluoroethylene coating (Teflon) on the working surface of the rod guide. The use of an additional "primary" gland made it possible to reduce the loading of the main seal. All these measures, combined with a frost-resistant shock absorber fluid of the highest quality (pour point down to -50 ° C), significantly increase the life of LYNXauto shock absorbers and allow them to be used in harsh conditions.

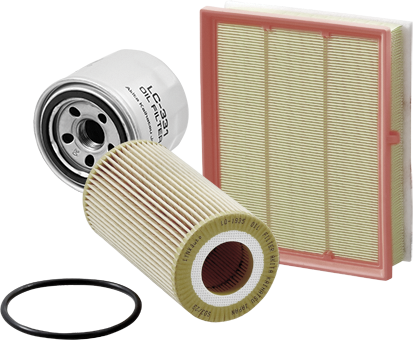

Filters

- Manufactured from the best materials and with the use of developments by Akita Kaihatsu

- Increased resource while maintaining quality indicators of filtration efficiency

- Reliable car protection

Due to the use of paper with increased dust capacity, air filters effectively protect the engine from dust and dirt from the environment, which ensures optimal air flow throughout the entire operating cycle and effective engine protection.

Cabin filters are available in two versions - standard and carbon. The filter paper has up to five filter layers, including an electrostatic layer that traps the smallest dust particles, which makes it possible to provide comfortable conditions in the car interior for the driver and passengers. In addition, LYNXauto filters additionally have an antiseptic impregnation that protects against pathogenic bacteria and microorganisms.